Click For Video

The small filling production line is consist of filling machine and capping machine,it is suitable for filling liquid into bottles and tighten bottle caps.The capping chuck can be customized according to bottle cap size and shape.It is widely used in food.

Parameter

- Machine Model:ZS-FAL90S

- Voltage:220V/110V 50-60Hz

- Machine Pump:Peristaltic Pump

- Production Capacity:About 5-15bottles/min(based on bottle size)

- Recommended Filling Range:80-500ml

- Max Flow Rate:700ml/min(based on water)

- Suitable Bottle Diameter: 30-70mm

- Suitable Bottle Height:50-150mm

- Suitable Bottle Cap Diameter:Can be customized

- Conveyor Width:10mm

- Filling Nozzle Diameter:OD 3.3mm

- The Whole Machine Size:About 1200mm*600mm*505mm

- Package Weight:About 20kg

The PLC control panel makes it easier to set parameters and control the machine to run. We can customize the language of panel according to your need.

With mini filling nozzle, it’s suitable for small-volume filling. It’s with anti-dripping function, ensuring filling accuracy. The height of nozzle can be adjusted according to bottles’ height.

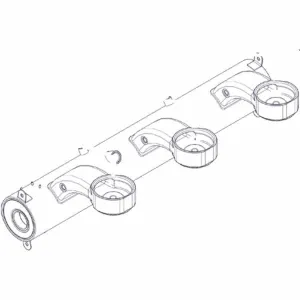

The capping machine is suitable for tightening ordinary bottle caps, like child-resistant caps. The capping head can be customized according to the size of bottle caps.

With peristaltic pump, the liquid won’t pass through pump during filling, ensuring product’s cleanliness. And it’s convenient to change tube when filling different liquid.

With electric eye, it can detect bottles accurately and control the machine to work automatically. Intelligent and efficient. The sensitivity of electric eye can be adjusted as needed.

With high-quality conveyor belt, it can transport bottles steadily. The conveying speed can be adjusted as needed. It is with waterproof function, which can ensure production cleanliness.